Explore the exhibition

What is a container factory like?

What is a container factory like?

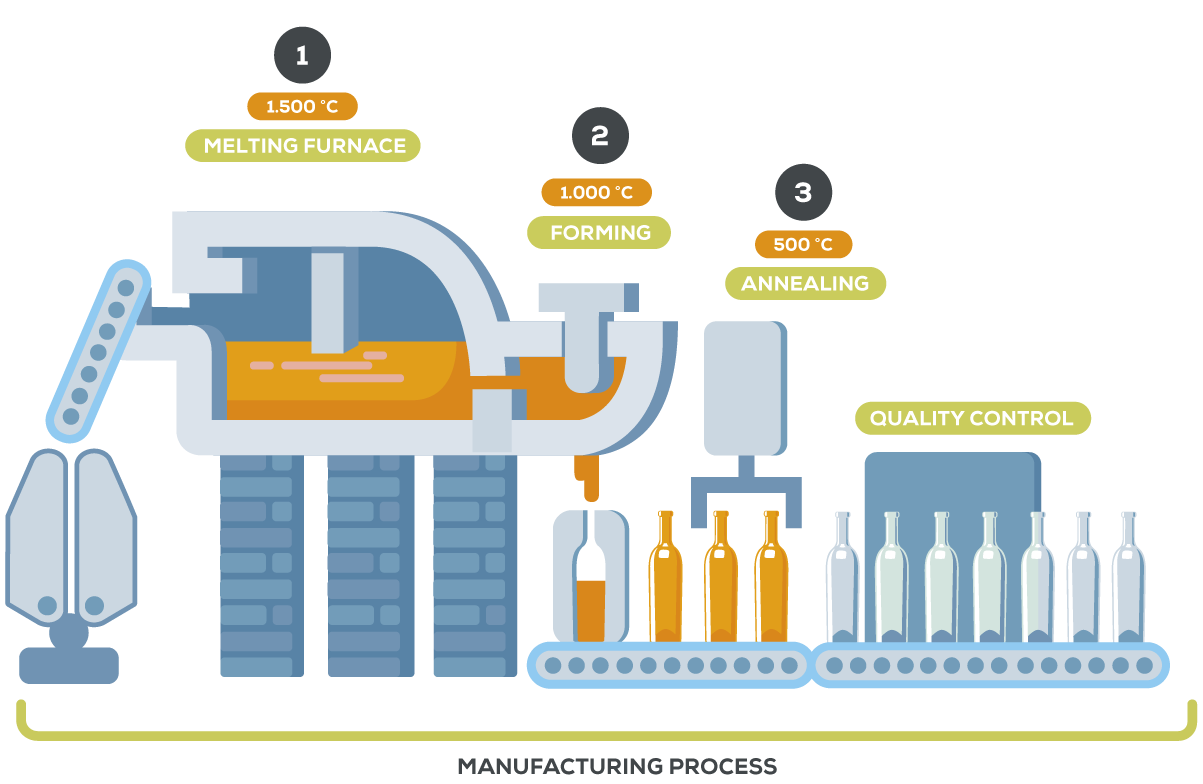

Glass goes through four fundamental processes:

Glass goes through four fundamental processes:

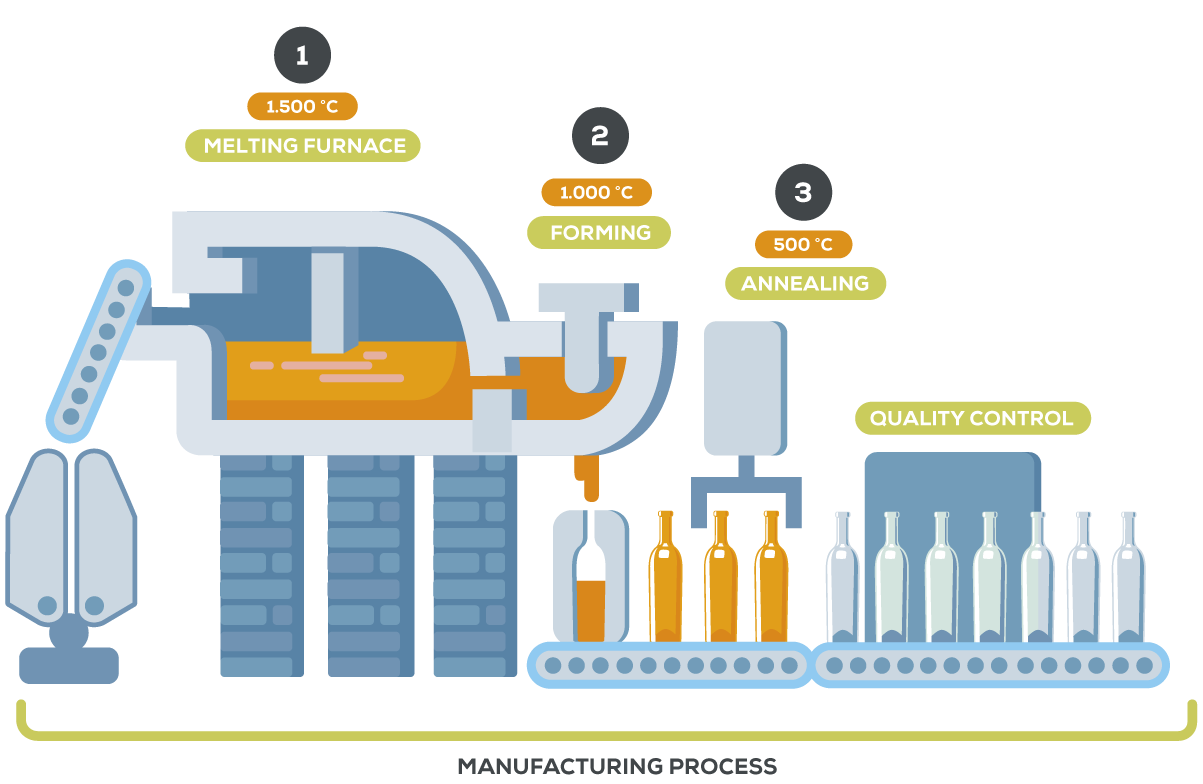

FUSION

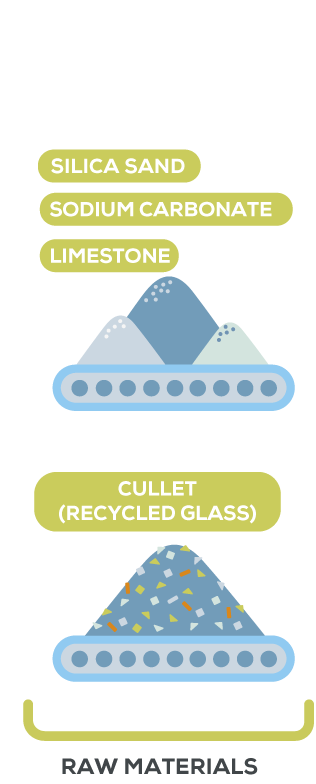

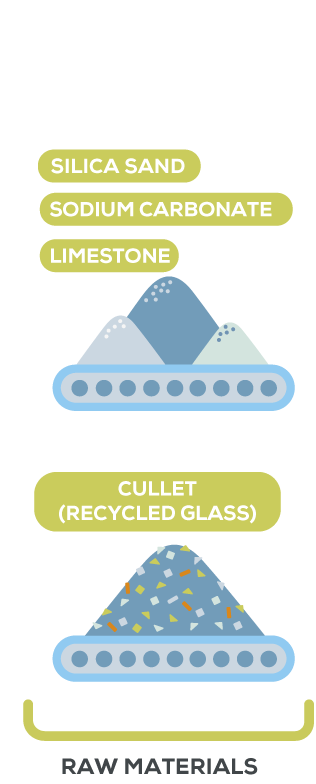

The manufacturing process for glass containers starts by mixing raw materials (silica sand, sodium carbonate, limestone) with the cullet, the empty container from recycling (clean and crushed) to feed the fusion furnace, where temperatures reach over 1,500 degrees centigrade (°C). These furnaces function 24 hours a day, 365 days a year throughout their useful life of some 12 or 15 years.

FORMING

After melting and refining (elimination of bubbles), the molten glass, now at around 1,000 °C, is cut into gobs with a weight equal to that of the final container, which are poured into the different moulds in the manufacturing machine. There, through a set of processes of pressing and blowing (blow and blow, or press and blow techniques), the new containers are shaped.

ANNEALING

Once the glass bottles or jars have been made, still at a high temperature (around 500 °C) they are placed in an annealing oven or lehr to prevent internal tensions forming because of rapid cooling. They are reheated by passing slowly through a tunnel, which then cools them in a controlled manner. In this way, the glass becomes more resistant.

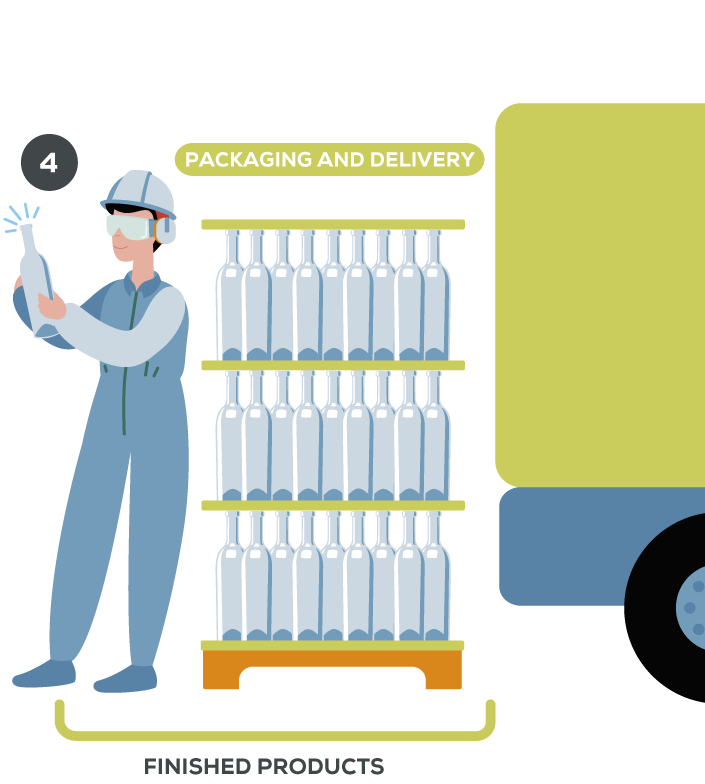

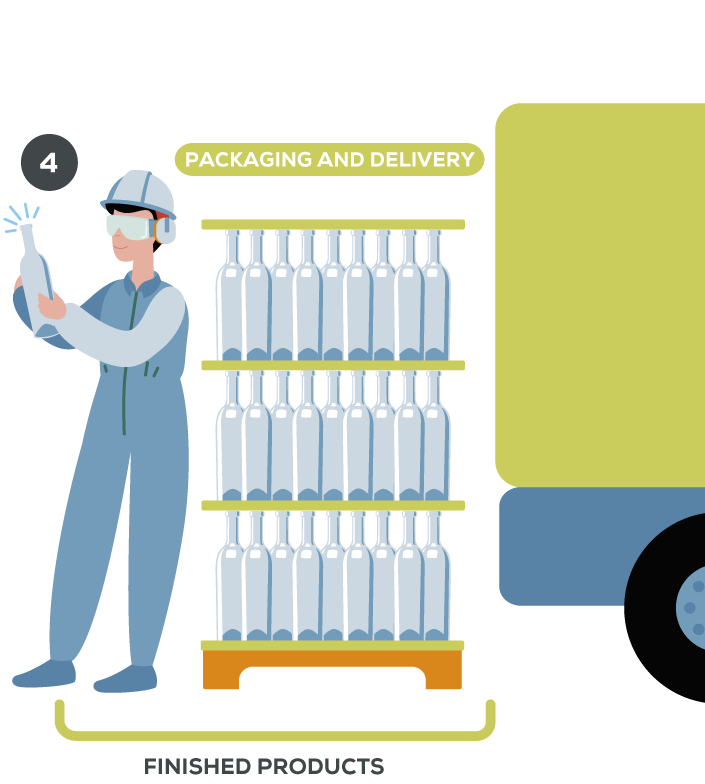

INSPECTION

Lastly, an aligner distributes the containers on the different quality control lines, for their subsequent packaging and transportation. A set of electronic machines control the 100% of the containers and highly specialized staff perform other control functions. Containers that fail to meet the foreseen quality demands are taken off the line to be recycled in the production cycle.

FUSION

The manufacturing process for glass containers starts by mixing raw materials (silica sand, sodium carbonate, limestone) with the cullet, the empty container from recycling (clean and crushed) to feed the fusion furnace, where temperatures reach over 1,500 degrees centigrade (°C). These furnaces function 24 hours a day, 365 days a year throughout their useful life of some 12 or 15 years.

FORMING

Tras la fusión y afinado (eliminación de burbujas), el vidrio fundido, ahora a unos 1.000 °C, se corta en gotas de un peso igual al del envase final, que se distribuyen en los diferentes moldes de la máquina de fabricación. Allí, mediante una serie de procesos de presión, prensado y soplado (técnica de soplado-soplado o prensado-soplado), se da forma a los nuevos envases.día y 365 días al año durante toda su vida útil, unos 12 o 15 años.u vida útil, unos 12 o 1

ANNEALING

After melting and refining (elimination of bubbles), the molten glass, now at around 1,000 °C, is cut into gobs with a weight equal to that of the final container, which are poured into the different moulds in the manufacturing machine. There, through a set of processes of pressing and blowing (blow and blow, or press and blow techniques), the new containers are shaped.ía y 365 días al año durante toda su vida útil, unos 12 o 15 años.u vida útidía y 365 días al año durante toda su vida útil,

INSPECCIÓN

Once the glass bottles or jars have been made, still at a high temperature (around 500 °C) they are placed in an annealing oven or lehr to prevent internal tensions forming because of rapid cooling. They are reheated by passing slowly through a tunnel, which then cools them in a controlled manner. In this way, the glass becomes more resistant.a y 365 días al año durante toda su vida útil, unos 12 o